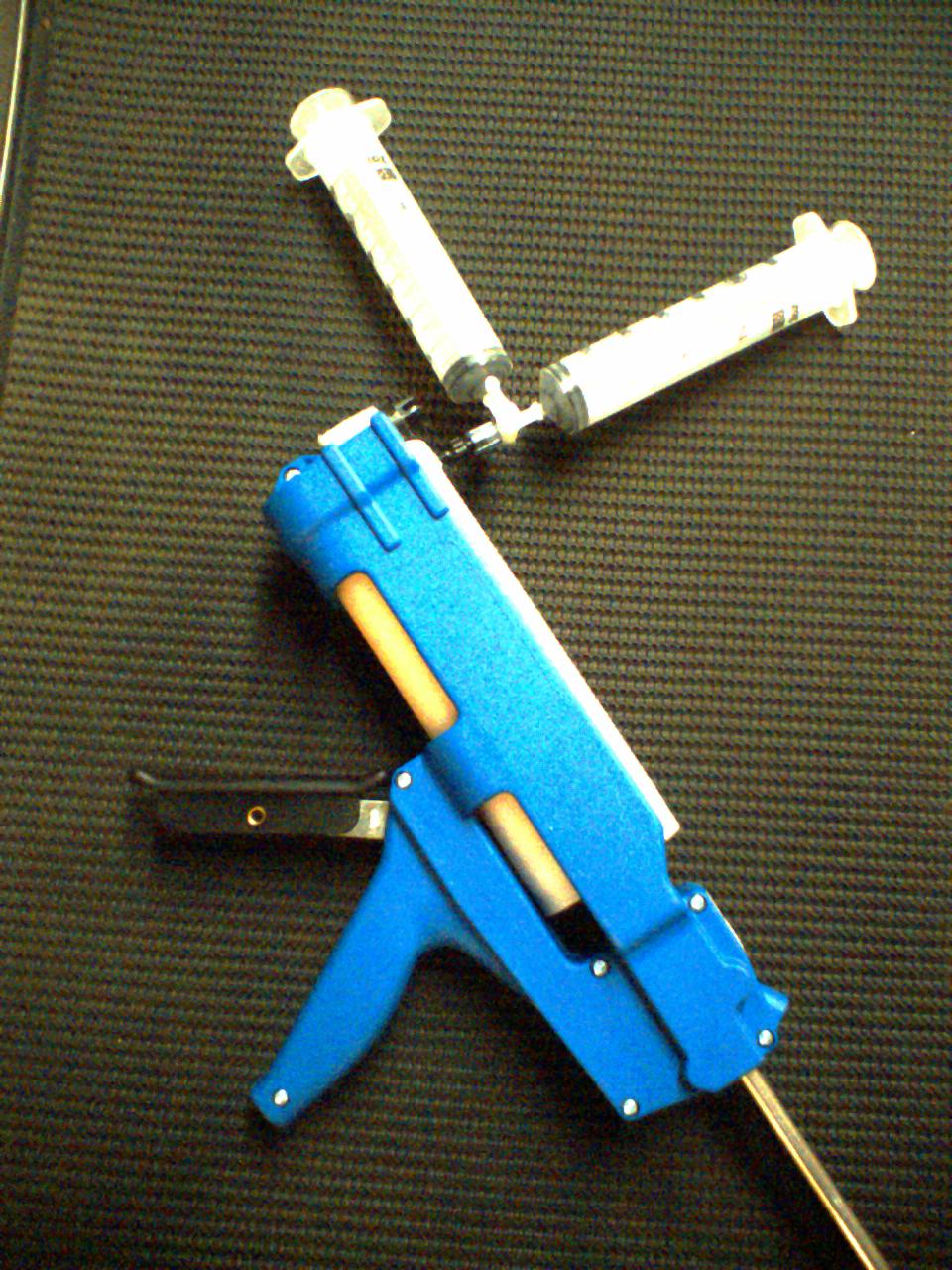

Re: Plexus MA425 small use pak.Hey Dave, I sent three packs in the box yesterday to you (and Robert) 'cause it sounded urgent in your last email. I was going to reply but have a very heavy load of things to do at the moment, so I ran out of time. To fill you in on my background concerns with repackaging this adhesive, The syringe packaging and manual mixing seems to me to be a more convenient system than the cartridges. I wasted 1/5th cartridge just filling the mixing nozzle and had to pump even more until the material was actually mixed (by color). Don't use it if its not mixed properly, it doesn't set. At the moment I'm not very happy with the syringes I bought. You can see a picture attached of how I get it out without exposing it to air or moisture. I'm not sure these precautions are really critically necessary for a 2 part system, but I do them anyway. The problem, I think, is that the syringe's BunaN plunger seal is letting the methacrylate solvent pass through the seal, right through the synthetic rubber. I didn't expect that but I noticed a bit of discoloration in the end of the 60ml syringes. I think that this batch will have a fairly short shelf life. I'll try to get a different "all polypropylene" type syringe for the next batch. You might be able to help it along by keeping it in the fridge at 4C until use as I do. Allow it a half day to get to room temp before using it so that it comes out of the syringe nice and easy. So overall, I think if you plan to use this stuff up fairly quickly after you get it you will be fine. I will continue to re-pack it just before I send it as well. Just use your judgment and don't use the dregs out of the bottom of the tube for an important job. Usage is fairly simple. Its a 10 to 1 mix. You have 60ml methyl methacrylate monomer emulsion in the big graduated syringe and 6ml blue colored peroxide catalyst in the small graduated syringe. There is 30-40 minutes of working time at room temp, so no need to hurry if you set up completely before mixing the parts together. Just like you would for epoxy/fast hardener. I think it is important to make sure there is no more than one part blue catalyst to 10 parts of methyl methacrylate monomer. This might cause improper crosslinking???. You are looking for a blue-green(aqua) uniform mix. The solvent will dissolve most plastics, therefore I mix it on an old ceramic tile or a bit of glass or in an old lab beaker. Just wipe out when you are done with paper towels. As always, protect yourself from high concentrations of solvent. This stuff smells "pungently" like the dentists office. Use it in a place with adequate air flow. If these kits are not working out, then however cumbersome, we will work out a system to get the large cartridges and the special gun around to the members who need it. Overall I think adding your own track to your mast is a fairly easy job and allows you to make the best possible job on the weight and protective finish of the mast. i.e. Sand off all the useless weight of black UV-sensitive epoxy and recoat with a UV resistant coat of either 105/special coating hardener or (like me) with 2 part linear poly perfection varnish. 2 part linear poly white might be even better. However, it is an extra step, and you could just light sand and coat the mast if the track is already on without getting too anal. Some sort of mast UV protection is really required though. Let us all know how it turns out please. Greg ----- Original Message ----- From: Dave Lindsey To: Greg Ryan Sent: Tuesday, August 29, 2006 2:05 AM Subject: Re: Plexus MA425 small use pak. Greg, I'm getting pretty close to needing the Plexus. At least I think I am. Can I order three of the smaller lots please. This may be more than I need but I would like to have extra for screw-ups. If I end up with an extra tube Ian can use it when he gets to that point. Thanks, Dave Lindsey CAN 046 |