Completing the pattern cutting

posted 2003 Sep 29

I cut the last few patterns from the hardboard this evening,

stations 0, 0.5, 6 & 7. After this, I will sand down the outer edges

of the hardboard exactly to the pattern lines, cut out the strongback

holes, and drill holes in the control lines (c/l and w/l). Then I'll

be ready to tack these hardboard pieces down to the particle board,

and rout around the pattern to get the stations.

Cutting the patterns

posted 2003 Sep 28

Today was the day for cutting the patterns out.

I got started around 1:30. After doing one small piece, I realised

I needed some eye and nose protection. I ran off to ACE hardware and

picked up some safety goggles and a facemask; I already had earplugs.

Manouvering the jigsaw (I bought a Skil

4580) was pretty easy. The supplied blade broke after about 1/3rd

of the way through; I picked up 6 new Bosch blades with 20 teeth per

inch, and they cut much better than the Skil blade did.

Another one of these blades broke as well, but this didn't phase me as

much (it was getting dull anyway).

I found it easiest to sight down the left side of the blade, which

meant cutting counter-clockwise around the patterns. Generally I

tried to cut off parts of the hardboard so I wouldn't have to make

many curved lines in the middle of the board, although that doesn't

work out all the time (sometimes the distance you have to cut isn't

worth it).

Each station took around 30 to 40 minutes to completely cut out,

depending on the size.

Construction begins

posted 2003 Sep 27

Construction begins!

Last night Tamara gave the OK to start building, even though we

haven't moved into the new house. I went down to Home Depot (Lowe's

didn't have 1/4" hardboard) and picked up the first elements for the

station patterns.

Greg on the mailing list had a great idea:

One more tip. If you are just about up to cutting your sections

now. Consider gluing the paper sections on thinner base material say 1/4"

hardboard (Masonite to you Aussies). Its easier to sand to the

exact size. Drill holes through the control lines then overlay it on

the station particle board and rout around it with a top ball bearing

1/2" diameter pattern/flush trim cutting bit (MLCS 2 flute carbide #

6506 1/4" shank $15) . This will leave you with an exact copy of the

section plan. You can mark the control lines on it and the scrap piece

is 1/2 inch larger all round and so with a 1/4" carpet padding will

perfectly fit the bottom of the hull when it comes time to rotate the

hull. It would also be a good template to help make the cedar cradle

and dolly.

That MLCS router bit is here.

This is a great idea, and it's what I decided to do. I picked up

three sheets of 1/4" 4x8 hardboard, and one sheet of 1/2" 4x8 particle

board.

This morning, after dropping Tamara, Tristan, and grandma at the

airport, I started in earnest. Per the instructions, I did the following:

- laid out the full sheets on the 4x8;

- drew a positioning line along the top edge and the side edge;

- marked the centerpoint, to make it easier to line up the

sheets when the adhesive is tacky;

- sprayed 3M Super-77 down;

- placed the pattern down, then smoothed it out from the centre

outwards;

- trimmed away the excess paper, 1cm from the outer edge of the

pattern;

- pressed the pattern down again, especially along the edges, to

ensure it's tightly glued.

All this took about 5 hours from start to finish. I used two

medium (270g) containers of Super-77, although I probably could have

gotten by with just one large one. Towards the end, I put a lot on

the hardboard; this ensures a good bond, but on the downside it can

get stuck to the guide on the jigsaw and cause a gluey mess stuck

there (in one case it ripped the edge of one of the patterns).

The Super-77 is pretty forgiving, although it sets up quickly.

Getting a good bond (especially if you're being stingy) has to happen

pretty quickly, within 20 seconds. You can the pattern off and

reposition it, but you have to do this quickly.

Stations

posted 2003 Sep 20

Well, I spent some time and pulled measurements from the plans

(have to do something to pass the time until we move and I can

actually start construction).

I bought 3 sheets of 18x24 vellum. I drew a line down the left

side of one of them, 1cm from the edge, and a waterline 20cm up from

the bottom. From these two lines, I carefully plotted a 10 cm x 10 cm

grid; along the 10cm lines I put a dot down every 2 cm. I then

stacked all the vellum on top of each other and used a pin to transfer

the points through to the other sheets (but didn't bother marking

them). Align the dots together and tape the three sheets together

vertically.

Now put the vellum down on a pattern, and line up the centerline

and the waterline. Using the 2cm dots to ensure the ruler is

straight, move 2 cm from the centerline or waterline each time and

move your ruler down first parallel to the waterline, then parallel to

the centerline. Measure the distance from the reference line to the

intersection of the hull line.

The results are pretty to look at, but

probably not terribly useful. Because the allowed margin of error is

¼”, there is likely enough error in my measurements and

the resulting numbers that you couldn't build a compliant boat from

the numbers. Bram's patterns converted to metric have precision to

four decimal places, 100x more accurate than these.

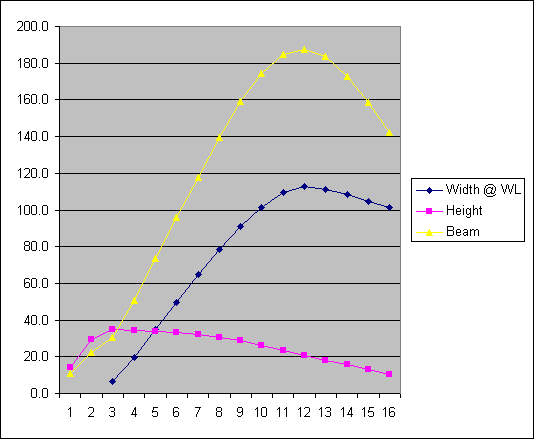

Measurements

posted 2003 Sep 10

Bram posted a while back that he had tried to use Kinko's large

poster copier to make copies of the plans, and that the results had

been less than satisfactory. The copies had come out by up to 1/4"

off. I've already been down there to make copies of the plans (just

before his post, actually) and thus I figured I would measure the

originals to see what the copies are up to. Here are the results (all

measurements in centimetres):

| Original |

|

Copy |

|

Difference |

| Station | Width @ WL | Height | Beam |

|---|

| 0 | | 14.4 | 11.1 |

| 1/2 | | 29.6 | 22.1 |

| 1 | 6.8 | 34.9 | 30.6 |

| 2 | 19.8 | 34.3 | 50.8 |

| 3 | 34.7 | 33.7 | 73.6 |

| 4 | 49.6 | 33.5 | 95.8 |

| 5 | 64.7 | 32.4 | 117.9 |

| 6 | 78.4 | 30.7 | 139.5 |

| 7 | 91.0 | 28.9 | 159.2 |

| 8 | 101.3 | 26.1 | 174.3 |

| 9 | 109.7 | 23.3 | 184.5 |

| 10 | 112.6 | 20.7 | 187.6 |

| 11 | 111.1 | 17.9 | 183.5 |

| 12 | 108.3 | 15.7 | 172.5 |

| 13 | 104.9 | 13.1 | 158.4 |

| 14 | 101.5 | 10.6 | 142.0 |

| |

| Station | Width @ WL | Height | Beam |

|---|

| 0 | | 14.5 | 11.3 |

| 1/2 | | 29.7 | 22.2 |

| 1 | 6.8 | 35.0 | 30.7 |

| 2 | 19.9 | 34.3 | 51.0 |

| 3 | 34.8 | 33.8 | 74.2 |

| 4 | 49.8 | 33.5 | 96.4 |

| 5 | 65.0 | 32.4 | 118.3 |

| 6 | 78.7 | 30.7 | 140.3 |

| 7 | 91.3 | 28.9 | 160.2 |

| 8 | 101.9 | 26.1 | 175.0 |

| 9 | 110.1 | 23.3 | 185.4 |

| 10 | 113.2 | 20.7 | 188.5 |

| 11 | 111.5 | 17.9 | 184.4 |

| 12 | 108.8 | 15.7 | 173.5 |

| 13 | 105.3 | 13.3 | 159.2 |

| 14 | 101.9 | 10.6 | 142.7 |

| |

| | | |

|---|

| 0.0 | 0.1 | 0.2 |

| 0.0 | 0.1 | 0.1 |

| 0.0 | 0.1 | 0.1 |

| 0.1 | 0.0 | 0.2 |

| 0.1 | 0.1 | 0.6 |

| 0.2 | 0.0 | 0.6 |

| 0.3 | 0.0 | 0.4 |

| 0.3 | 0.0 | 0.8 |

| 0.3 | 0.0 | 1.0 |

| 0.6 | 0.0 | 0.7 |

| 0.4 | 0.0 | 0.9 |

| 0.6 | 0.0 | 0.9 |

| 0.4 | 0.0 | 0.9 |

| 0.5 | 0.0 | 1.0 |

| 0.4 | 0.2 | 0.8 |

| 0.4 | 0.0 | 0.7 |

|

Pity. It looks like the Kinko's poster copier is out about 1 cm in

200 (about 0.5%), and it adds width, not height. The errors are all

quite consistent, right between 0.4% and 0.6%. Since the class only

allows an error of 1/4", this won't cut it. A $50 photocopy job

rendered useless.

What I plan to do is create my own lofting sheet from the plans,

and use the masters for the templates and station molds.

Note that point '2' on this graph is really station 1/2, so the

slight deviation from a nice curve makes sense, since if it was

correctly placed the graph would be smoother.

My number

posted 2003 Sep 1

Bram has posted sail numbers. I am USA 012.

Page 59 of 62

« First

…

«

57

58

59

60

61

»

…

Last »