Swift Regatta 2008

posted 2008 April 21

I just returned from the North American Swift Solo Championships 2008. This year's regatta was

held in Fort DeSoto Park.

The park itself was a truly spectacular location: clean sandy beaches, warm water, hot sun, and

pleasant breezes every day. It's hard to imagine a better location to spend a week in early spring

(avoiding the grey skies of Seattle). All of our activities took place at the east beach; we

visited the North Beach (winner of the 2005

Beach of the Year award) one evening as well.

The regatta ran from April 10 to 20. The truck arrived on the 10th, and everyone pitched in to

unpack it. Repack day was the 20th, with the expectation that everyone would fly out that

afternoon. I arrived a day late (couldn't leave work) and left a day early (I wanted to see my

family for a day before returning to work) - so I was in the doghouse for not helping out with

unpacking and repacking the truck up for those two days.

Day 0 (Apr 11): The first day was a travel day. Up at 3:30 am to catch the Shuttle Express to the airport, then the

hurry-up-and-wait of travel. I flew Southwest; thankfully it was pretty painless. First to

Chicago (Midway), and then to Tampa. I arrived late Friday afternoon and met up with a fellow

Swiftie from Calgary, Keith Deller; we picked up our rental car, found our way to the park and the

right beach - we didn't know it was the east beach - and said hello to everyone. And dragged our

boats out from under the trees and ensured they had made the trip successfully, as well as all the

gear. I went out with Mark - I shared his campsite for the week - and we found a spot outside the

park to park his RV and crash for the night (we booked too late to get one for the full week).

Day 1: Sorting out the rig. When I

left Seattle I knew I had to splice more parts onto my mast; this was the day to do it. I:

Day 1: Sorting out the rig. When I

left Seattle I knew I had to splice more parts onto my mast; this was the day to do it. I:

- Spliced the shroud tensioners on, and the cap shroud levers (because I have an adjustable

forestay, I have levers on my caps rather than the primaries, different from many of the Swifts

there).

- Determined the tip of mast to the lower aft hull is 23’9” to 23’11”.

- Re-spliced the caps and primaries - the first attempts we did in my garage weren't long

enough. I agonized over ripping these out, but eventually went for it.

- Re-spliced the lowers to make the top splice go through the entire line, so there was no

chance it would pull out (similar to how the rope ladder is made).

- At some point of doing all this, Bill, Keith and I were working on my jib halyard, and Bill

pulled the halyard through and a tail of line poked through the block. Bill says "What's that?"

and I say "I don't know" - and then it disappears. And it was the halyard. And I freaked.

Luckily with a little dancing, a paperclip, some bright green mason line, and a lot of patience,

we managed to pull it back through the block. But it was a tense 30 minutes, given that it took

me all day to run those damn halyards.

- Rather than use the wire Bram gave me for the forestay, I spliced a soft one from lightning

rope: 189” long.

- All that complete, I prepared to step the mast. I had to cut the rear off the tang, so there

was at most 1/4” all around the pin hole and the tang could rotate with the pin in. That

meant I could step the mast. Whoohoo!

- After dinner, I drilled a hole for the boom quickpin, and attached the boom and boom vang.

It was a long day - rigging all the way into the evening. But the boat is looking good; I'll be

sailing soon. Back to the campsite, and crash in Mark's RV.

Day 2: More rigging. Started out

with a run to West Marine to pick up all the bits and pieces I needed: swivel blocks, quickpins, and

cleats. Breakfast at McDonald's - surprisingly good - and then back to rigging. Today, I:

Day 2: More rigging. Started out

with a run to West Marine to pick up all the bits and pieces I needed: swivel blocks, quickpins, and

cleats. Breakfast at McDonald's - surprisingly good - and then back to rigging. Today, I:

- Put numbers on one side of my mainsail. I wanted

to get the sail up, so I could position the vang collar, so I didn't bother with the other side.

- Hoisted the main. The halyard was slightly long,

so Ron, Mark and I tipped the boat over to examine how to adjust the halyard appropriately.

- Once the main was up, I could determine the correct position for the key for the vang collar.

The arm should be perhaps 3” from the mast (i.e. tipped fairly vertically) - and that fixes

the initial location of the collar. I taped the top and bottom of the vang in roughly the correct

place, and then centered the key top to bottom in the collar. After really rigging the boat, it

probably should have been a bit lower - having the cunningham tight seems to make a difference.

- I tensioned the rig (and adjusted splices to get there). The primaries should be around 21,

the caps 8.

- I rigged the relativity control. It took some

doing to ensure this was correct; the picture is of Chris Wickham's boat, which has a similar

setup to mine.

- I rigged the jib halyard - the halyard comes out

of the mast and attaches to a block with a hook on it; the block then goes down to two small

blocks at the base of the mast and out to the wings. The secondary rope was what I needed to do.

Another late night rigging, then dinner at Billy's, which was literally up the street from

the beach. We went here for dinner a bunch (it got tiring).

Day 3: Still working on the

rigging. Throughout the past few days I kept thinking "I'm only a half-day from sailing" - but

there was always one more thing to do. Perhaps that's the nature of a builder class. Started out

with another trip to West Marine, this time for #2 whipping twine, a harken block with flat cheeks

on one side (for the vang arm), bullet blocks, red balls, g/flex, line. Stopped for breakfast at

McD's again. Then:

Day 3: Still working on the

rigging. Throughout the past few days I kept thinking "I'm only a half-day from sailing" - but

there was always one more thing to do. Perhaps that's the nature of a builder class. Started out

with another trip to West Marine, this time for #2 whipping twine, a harken block with flat cheeks

on one side (for the vang arm), bullet blocks, red balls, g/flex, line. Stopped for breakfast at

McD's again. Then:

- Drilled holes in the mast for the vang key, and flattened the holes in the key itself so the

rivets wouldn't stick out. That done, I riveted the key in place. This was amazingly liberating

- getting that key on there was something I had wanted to do for a long time, as it was the last

bit of "real building" (involves a drill, I guess) which had been hanging out there. I was

incredibly relieved once that was done.

- Bram checked my rig and relativity setup.

- We had a beach lunch (probably a run to Subway, near Billy's), and then spent an hour discussing class expansion and how to make it possible.

Lots of people want to sail the boat, not everyone wants to build: so the question is should we

find a builder to build the hulls, to make it easier to get into the boat. Consensus: yes.

- I adjusted the transom bridle to the right length.

- I rigged my spinnaker. I've seen Bram do this

"the one true way" twice now, but I've forgotten how he does it - I'll have to get the

instructions once more.

By this time the wind was really howling, and the temperature had dropped - a storm was blowing

in from the north. A few brave souls went out for a sail, but it wasn't without some damage: one

Musto sailor fell into his mainsail causing quite a

hole. Keith, Robert and I went up to the north beach

to check out the conditions - it was blowing sand and

just howling. The windsurfers liked it though. We

returned to Billy's (again) for dinner.

Day 4: Lay day. Given that the

weather sucked, we took a lay day a day early. I

changed into pants (gasp!) and instead of hanging around the beach as the rest of the crew did,

Keith and I went to the Dalí Museum in

St. Petersburg. I was really impressed with this museum - they had a lot of Dalí's work, as

well as some additional pieces in from the Tate Modern.

Day 4: Lay day. Given that the

weather sucked, we took a lay day a day early. I

changed into pants (gasp!) and instead of hanging around the beach as the rest of the crew did,

Keith and I went to the Dalí Museum in

St. Petersburg. I was really impressed with this museum - they had a lot of Dalí's work, as

well as some additional pieces in from the Tate Modern.

Next we went up to visit Tarpon Springs. Tarpon

Springs used to be known for it's quiant Greek fishing village, but most of the quaintness seems to

have been lost. We drove back down via Gulf Boulevard on the keys along the edge of the

coast; it was perhaps 20 miles and at times only a two-lane road thick. It reminded me of being

on the atolls in French Polynesia.

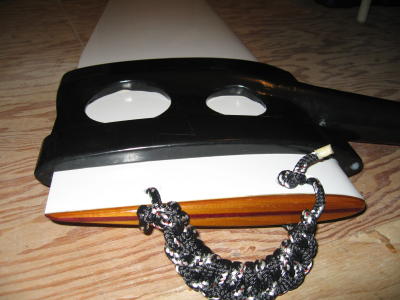

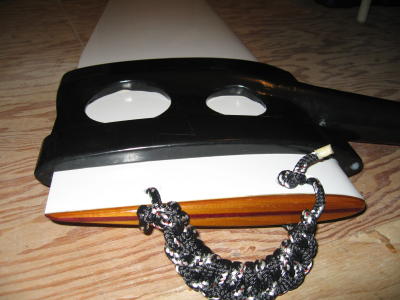

The day wasn't a complete loss, however. I did I did put the rope through my rudder and centreboard to form a handle. Keith provided the black

line: can't put marks on it to tell how tight everything is. I also took pictures of Bram's kit of

many things:

one

two

three

four. He seems to always have the part you need.

Dinner was a Cuban restaurant: not especially good. It's seafood focused, with plantain bannanas

(lightly breaded and pan fried, I think). I left with a nasty stomachache.

Day 5: This was the day to

transition from rigging the boat, to actually sailing it. I started out by visiting the actual fort in Fort DeSoto, and getting my history lesson

for the day. All that's left now are a few impressive guns and the battery, but they were still

pretty cool.

Day 5: This was the day to

transition from rigging the boat, to actually sailing it. I started out by visiting the actual fort in Fort DeSoto, and getting my history lesson

for the day. All that's left now are a few impressive guns and the battery, but they were still

pretty cool.

Once I reached the beach, I finished the last real "building" piece I needed to -- drilling the hole for the vang collar pin, so that the

vang arm would be correctly positioned on the mast. This was another huge relief -- somehow getting

that hole drilled was a major mental hurdle to overcome, and once it was complete, I was much more

relaxed. Now I might actually be able to get my boat on the water.

Now that all the newbies had their boats pretty much assembled, it was time for the actual

clinic. We suited up as if we were going out on the water, tensioned up the boats, and then Bram

walked the entire group through doing tacking, gybing, and

hoisting on our own boats. It was a great experience -- it helped make the motions on the boat

much more intuitive and greatly reduced the "fear factor" of getting into such a high-powered boat.

I did a bunch of trapeze tacks wire to wire, as well

as a gybe or two. Bram suggested we split up and continue to practise (which would have helped a

lot as well -- it was taking me some time to pick up the lines in the right order and place the feet

in the right way), but we ran out of time. I fixed up a few problems the clinic identified: the

shims for the mainsheet cleats should be alternate directions (not tilted inward), and the tennis

ball for the trapeze handle should be even with the top of the boom (mine needed to be spliced

further up).

Next, fully geared up, Bram took a number of us out in the launch, and we zipped around the water

watching the techniques of the more experienced sailors. This was helpful as well, particularly

after having attempted the techniques on land: seeing actual on-the-water tacks was really useful.

That pretty much filled up the day. We had an early dinner: a bar-be-que on the beach, and afterwards held the Swift

AGM: we discussed the finances, future of the class (should we build Nomex hulls?), location of the next regatta (Huntington Lake, Bram's favourite regatta

location), and Bram's intention to reduce his time spent on class matters and his secession plan.

Once the AGM was done, a number of us went out to an ice cream parlour in Long Key.

Day 6: First day of the actual

regatta. Keith and I started out with a trip to McDonald's for breakfast again (good coffee,

especially at $2 for a giant cup, and OK egg McMuffins at $1 a pop - the cheese isn't as good as

home. Back in Seattle, I saw a McDonald's billboard on a bus saying "$4 for coffee is stupid" - and

I have to say, they do have a point.) and returned (just) in time for the skipper's meeting. I took

a few pictures of Chris Wickham's cunningham setup -

he runs his cunningham out through the swivel cleat, splits the line to either wing, and has it run

to his trapeze handle.

Day 6: First day of the actual

regatta. Keith and I started out with a trip to McDonald's for breakfast again (good coffee,

especially at $2 for a giant cup, and OK egg McMuffins at $1 a pop - the cheese isn't as good as

home. Back in Seattle, I saw a McDonald's billboard on a bus saying "$4 for coffee is stupid" - and

I have to say, they do have a point.) and returned (just) in time for the skipper's meeting. I took

a few pictures of Chris Wickham's cunningham setup -

he runs his cunningham out through the swivel cleat, splits the line to either wing, and has it run

to his trapeze handle.

Keith and I decided to join Dave Ellis (our one-man race committee) on the committee

boat, as flag-raisers and photographers. Dave was a blast - he regaled us with stories of

buried treasure all around the Florida panhandle, pirate booty, friends who had come oh-so-close to

identifying the trees/railroads/rocks under which said booty was buried, his adventures in sailing

5o5's, etc. Spending a few hours on warm water watching Swifts blast by

and listening to these sorts of stories was an entirely enjoyable way to spend the early afternoon.

We ran three races in moderate wind before packing it back in - the wind was starting to die

down. That presented the perfect opportunity for the newbies, however: go out and get wet (sail)!

We came in and rigged the boats up, rigged ourselves

up, and went out sailing.

And I have to say, it was fantastic. I put the daggerboard

in... and it fit! It slid through the hole and didn't float up! The rudder worked too! When I

capsized, the daggerboard didn't break when I climbed on! The boat floats! It sails!

In-CRED-ible! There were a couple problems - the mainsheet still wasn't cleating correctly, the

port-side trap ring didn't seem to want to stay attached to my harness, and everything was still

stretching out so the main didn't go quite to the top of the mast. But still - I

sailed my very own boat!

Once I got out there, I cleated my main (most of the time) and tried steering to get a feel for

the boat. I also spent a bunch of time in the water - I tipped over around six times, and at one

point I flipped the boat from one side to the other about three times before I actually got it back

to vertical again (it takes some time to figure out how to control the speed of the boat as it

rights itself). I would sail up the coast, tip over, let the current drag me back down to the

beach, right myself again, and repeat. Overall this strategy worked pretty well. I practised

tacking as well - although it's clear I'll have to work on the movements a bit more before it really

clicks.

I returned to shore, pulled my boat up, and drank

some gatorade. And cheered! After that it was a shower (get rid of all that

salt), dinner at a new place, Sea Critters Cafe

(and had margaritas, jambalaya, and key lime pie; really good), and back to camp to sleep.

Day 7: Largely a repeat of

Thursday. We had to move our campsite (Mark wasn't able to get a complete stay in the same site,

because we booked late; we moved from 140 where we were most of the week

to 191). Then it was off to McD's (same as before), West Marine (bolts for battens, small shock

cord), and back to the beach.

Day 7: Largely a repeat of

Thursday. We had to move our campsite (Mark wasn't able to get a complete stay in the same site,

because we booked late; we moved from 140 where we were most of the week

to 191). Then it was off to McD's (same as before), West Marine (bolts for battens, small shock

cord), and back to the beach.

We went out on the committee boat and helped Dave again, raising and lowering the flags, and taking pictures and watching the giant pelicans diving

for fish in the shallow water. After the first race, the wind completely died away, and after a

very slow final downwind leg - a number of people didn't finish in the time required by the notice

of race - everyone returned to shore for lunch.

I dallied on the beach, eating a few snacks and lunch, doing a bit of extra work on my boat

(playing around with the bevels on the mainsheet cleats), drained my boat (I forgot to do that yesterday: likely

water is getting in through the bolt holes. I'll have to seal them), and generally getting ready to

go. Dave went back out again and started up the second

race of the day, while I prepared my boat for a sail. Once the second races of the day were

done, I went out for the second sail. My objective was to avoid yesterday's capsizes and

spending all my time in the water: perhaps get close to capsizing (otherwise how do you know you're

pushing the limits?) but not spend a lot of time in the water. I wanted to get a feel for steering

and weight management: How do I manage the puffs, how do I swing out on the wire, and when going

downwind, where is the "twilight zone", where you don't know if you should head up or bear off in a

puff?

Overall it was fabulous. Again. I was out there quite a while, until the wind started dying.

Despite the fact that it was marginal trapping wind and it was puffy (coming over the land), it was

still incredibly enjoyable to be out there and racing along in the water. And I didn't tip - I just

went up and down along the beach repeatedly. And I saw a few dolphins between me and the shore, too

- another sight to behold.

Once the wind completely died away, I returned to shore, dried off my spinnaker, and packed up a

bit. Robert, Keith and I cooked dinner on the beach (well, Robert cooked and I went on a beer run), and then I

returned to the new campsite to pitch the tent and get ready for bed.

Day 8: Last day on the beach, and

it was all to be spent packing up. I broke down camp and packed it in my big green duffel. Then

down to the beach, and helped everyone get off for

another day of racing. Then started to work on my boat: removed the boom and padded it up.

Unstepped the mast. Taped everything together and

lashed lines down. Put on the boat cover. Mast in the mast bag. Taped the halyards and stays to

the mast. Taped the lids onto my work boxes. Rolled the boat over to the right spot, and put my

bags and boxes underneath.

Day 8: Last day on the beach, and

it was all to be spent packing up. I broke down camp and packed it in my big green duffel. Then

down to the beach, and helped everyone get off for

another day of racing. Then started to work on my boat: removed the boom and padded it up.

Unstepped the mast. Taped everything together and

lashed lines down. Put on the boat cover. Mast in the mast bag. Taped the halyards and stays to

the mast. Taped the lids onto my work boxes. Rolled the boat over to the right spot, and put my

bags and boxes underneath.

By noon it was time to get on the road. I said my goodbyes, changed into pants (hot!), and drove

into the city to catch my plane. It was a looong flight to Denver and then home. Courtnay picked

me up, and I was sleeping in my own bed that night. How relaxing!.

Home: Overall it was a fabulous

trip. The weather could have been better -- the ends of the trip were hot (in the 30s) and the

middle was really pretty cold (7 or 8°C). As I mentioned to the West Marine guy, I went to

Florida to escape that weather, and it wound up following me down. But overall it was relaxing,

enjoyable and a resounding success. It was great to see all the Swift sailors again, to sail my own

boat, and to be out in the nice Florida sun all day every day, or relaxing in the shade of our regatta tree. I

wore flip-flops the entire time. It was heaven.

Home: Overall it was a fabulous

trip. The weather could have been better -- the ends of the trip were hot (in the 30s) and the

middle was really pretty cold (7 or 8°C). As I mentioned to the West Marine guy, I went to

Florida to escape that weather, and it wound up following me down. But overall it was relaxing,

enjoyable and a resounding success. It was great to see all the Swift sailors again, to sail my own

boat, and to be out in the nice Florida sun all day every day, or relaxing in the shade of our regatta tree. I

wore flip-flops the entire time. It was heaven.

(Not to mention: it snowed on the Sunday I

returned. How's that for a welcome back present.)

Loading up

posted 2008 April 7

With the boat (and mast) out of the house, this week was a bit of a "taper" week -- spend time

getting all the other things necessary for the trip ready to go. It's good this happened too --

there would be too much pressure to continue to work on final things on the boat to get other

(important!) things done.

So, I packed the food & cooking container

(blue). There's all the actual sailing gear I'll need.

I also determined everything I'd touched in the past

week, and put it all in another container. I verified

the sails looked ok. I packed the camping gear (tent, sleeping bag, chair, thermarest).

Throw that plus the bike into the car, and I'm good to

go.

There wasn't zero work on the boat - I drilled a couple extra holes in the rudder and centreboard, so I wouldn't have to deal with knots in the

handles - Bill suggested this. (He also has a very pretty cap for his daggerboards; perhaps I'll

have to do that as well...)

Bill's rudder cap and handle.

On Saturday, I arrived bright and early at Shilshole to load the boats. Bram had organized a big truck to load everything on to; we fit four Mustos and another six Swifts in. Each boat is

lashed to it's cradle and dolly. The full dolly/cradle/boat is then lifted overhead and placed on

beams which attach on to the sides of the truck; a strap then goes around the dolly beams and the

cross beam, is tied to the sides, and pulled taunt (stopping both up & down and side-to-side

motion). Along the sides and under the boats, all the extra gear gets stashed.

Crusher was fourth in; it was funny looking up to

see the hull. All the masts were loaded along the side

(with plenty of padding). All full up.

Peggy Watt also took a bunch

of pictures; here's my boat being loaded:

In the truck.

Heave ho, and hold while the beams are put in place.

Crusher gets wet

posted 2008 April 1

Crusher gets wet!

Ok, maybe she isn't quite ready to sail yet, but getting wet is still a tremendous milestone.

I started out this week just trying to get a bunch of little things wrapped up.

- Complete the mast base. I screwed the Harken spinnaker block down, then drilled the

hole for the pin by placing the base in the mast step

and scribing the circle on the tang. That complete, I elongated the hole, so I can rake the mast (by about

10°).

- I installed the mast base. First, I levelled the spreader holes. I cut the U shape at the

end of the mast (the spinnaker halyard exit hole), and sanded the inside of the mast base for a

tight fit. That complete, I tapped the base into

place, and screwed it in with two wood screws.

- I spent an evening cutting bolts for the centreboard and installing them. I went with the acorn nuts and not the

ones which go flush (I don't have room for those).

- I screwed the tiller extension mounting

plates into place. I had to enlarge the holes on one side so the nuts would fit in;

I hope they don't actually come loose. (Epoxy would be the next step.)

- I installed the shackle for the base of the

lowers. To do this, I took the chainplate off the bolts, punched where the hole should be,

and then went through two drill bits dilling the hole. The shackle is the lower terminus of the

lower shrouds.

Bram came over on Friday and we completed a bunch of other things as well:

- Installing the tiller extensions: There are two pieces to this. First, the

extensions are put in place and a zip-tie is used to hold

them down so they don't pop off, with tape to cover it up. Then the tubing goes over the

shock cord, and the cord is zip-tied to the extension (with a double wrap of the tie). Then cover in tape, and it's done.

- String the forestay adjuster: These

are just like the shroud tensioners, except for the big U shackle which ends the line. The line then goes down into the forestay fitting, back to a bullet block, to the two deck blocks, and out to a (newly

installed) cleat on the wing.

- Install a new cleat: For the forestay adjuster, there needed to be another cleat on the wing. The back screw is about 3”

long, and drilled into the backing block for the chainplates under the deck. The front screw just

goes strait into the deck, and is about 1 1/2” long.

- Screw the masthead in place: I drilled the first hole a wee bit too far down;

it barely cut through the base of the crane insert. Measure twice... I used wood screws with the tips ground off so they don't catch

anything. To drill the hole without drilling the halyard, I tied the halyard to a thin line

(mason's line), and carefully pulled it in, then positioned everything and drilled.

- Install the shackle on the shroud

tensioners: The shackle has the threads drilled out, so a quickpin will fit

through. To get it in place, I had to remove the lower bolt from the block, slide it on, and

re-screw everything together.

- Splice the lowers: T-bolt on top

held in place with a through-loop, followed by a splice of the tail into the core. The bottom

uses a splice into the core, with a tail for

adjustability. Make sure they're 3” *longer* than the mast.

- Spice the end of the spin sheet: Because I had pulled the core of this sheet

out once, I was extra careful to ensure that I had pulled as much core back inside before cutting

it off for the cover. Getting these things spliced took a while: I went through about five

splicing loops before I got it to work. That complete, splice using the "through-the-line, whip around, ends go

under the rounds" method.

- Installing the boom vang: I ensured the vang arm would fit, cut the bolt to length, and drilled

and installed the cap nut on the other side.

- Install the spin sock: Once the velcro was in place on the forestay fitting,

I cut off a bit of excess non-skid on the deck, and pressed the tail end of the sock in place.

Then, drill three holes in the launcher throat, dig out as much foam as possible, and fill with

epoxy. Screw the sock in place. That complete,

install the retrieval block.

And that was pretty much it; I ran out of time. It was time to get Crusher wet. Of course,

there's nothing quite like snow during the final

rigging session or for boat transport. Snow in April

(almost). Lovely.

Ron (graciously) agreed to help in getting my boat down to the marina, to prepare for loading

(thanks!). I'd been too busy building to be able to source trailers, or hitches, or any kind of

trailer bed... &c. Fortunately, Ron's dolly is exactly the one I have, and so fitting it on to

the bed was easy.

He came over on Sunday morning, and we did a series of firsts. First time in the open air. First trip at faster than 1 mph. First

time at the marina. A product shot - ready to launch. And: wet. We had to drop it in so we could get it over to the correct spot on the dock

- I'm borrowing Bram's spot for the week. Once we manoeuvred over there, we pulled it back on the dock (easy to do with

two people: perhaps harder after you've capsized 20 times and are returning exhausted), and wrapped it up. Now the garage looks pretty barren - I even pulled the workbench further into

the garage. I don't know what I'll do. (It will probably be slowly usurped by all the floatsam of a

living house...)

There are still a few things to do before it's sailable: splice in the primary and cap shrouds,

rig the forestay, attach the vang key to the mast, rig the control lines. But it's very, very

close...

Day 1

Day 1 Day 2

Day 2 Day 3

Day 3 Day 4

Day 4 Day 5

Day 5 Day 6

Day 6 Day 7

Day 7 Day 8

Day 8 Home

Home