Sanding the bowpiece

posted 2004 Jul 26

So, with the bulk of the bowpiece cut to fit and the first

application of epoxy into staple holes, it's time to... wait for

it... sand some more!

I thought about renting a hand-held belt sander at around $13 a

day, but finally just broke down and bought the cheapest I could find,

a Ryobi, for $50. It positively rips through wood, and I probably

could have just rented, but now it's on hand for later projects. So

with my brand-spanking-new belt sander I hit the bow and went from rough to smooth in pretty much 30

minutes. The biggest challenge here is to try and ensure that you

don't remove too much material, especially towards the knucle where

the bowpiece is relatively thin.

Next was rounding the bow out. I used the method suggested

by Greg:

Mark the centerline continuing down the front face with

pencil. Then divide the front sides into 4 with straight diverging

pencil lines from the top point to the bottom . Use a straight line on

the side of the block back from the front corner about the same size

as one of the quadrants on the front face. To make short work of the

shaping, use a belt sander to flatten the front corner to the lines

you have just drawn. Making and equal bevel on both sides. Divide the

front faces again and bevel that from the centerline. Use this

technique of successive approximations to a fair curve until it looks

right. If you divide up both sides carefully like this the shape will

be perfectly equal both sides. Touch it up with the hand sanding

block. Fill the thirsty end grains now with unthickened epoxy to

prevent dry lay-up when glassing the bottom.

I made sure that the front face was square to the rest of the boat

(although station 1/2 was about 1/8" out of square it seemed, so I

still was careful to eyeball everything to ensure it looked correct).

I then followed Greg's

directions, and it worked out very well - after touching it up with a

block, it looks quite

nice. The final bowpiece is 6" wide, 5" deep, and 13"

high - so next time I can save a bit on cedar costs. ;-)

Just to pass the time, I filled all the staple holes again and

faired a bit more.

Cutting the bow

posted 2004 Jul 18

In between two hour sanding sessions, I decided I should begin

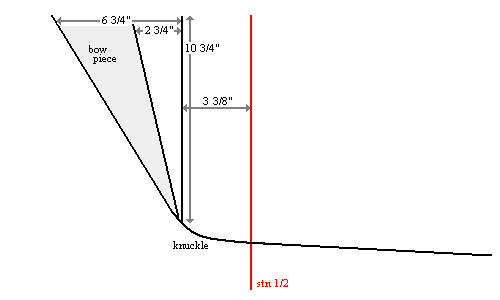

attaching the bowpiece to the bow of the hull. With my instructions and math I started out by drawing a

picture of exactly what was required:

Initially quite a bit

of material has to be removed. It's a bit scary to be cutting all

this off - especially having constructed it so lovingly. But you can

always fill in the gaps with filler, and anyways, the resulting bow is

going to be hidden under black graphite, so it's all invisible.

I carefully measured

everything, to within 1/4" generally - so I wanted to be pretty

accurate in the cuts. Once done, I managed to cut a bit too far aft

of where I needed to. Part of this was because the lines curve aft

due to the concave hull at this point, and partly because my pull saw

has a tendency to curve to the right. I should have kept a 1/8"

buffer and sanded it off afterwards.

Another mistake was I still had the stabilising 2x2 sticking out

station 1/2. I should have cut this off. As it was, I used a circle saw to cut it off,

and cleaned it up a bit with the rasp.

I hot-glued the bow

piece in place. The hot-glue is strong (three dabs held that entire

thing in place), and sets quickly (within 10 seconds). Once it was

tacked in place, I crawled

underneath and put in a fillet of epoxy/406 with some fibreglass tape - later on

I'll reinforce this, just to be sure.

While that was curing, I set about filling staple holes with

straight epoxy (with a wee bit of 406 mixed in). The 406 reduces how

much the epoxy runs, but makes it more visible.

Next up was cutting off the excess of the bowpiece. To start with,

I aligned my pull saw to lop off the very front of the bow. I made

sure the blade was parallel to the part of the kunckle which was at

the right angle, and then cut it all off. The blade had a tendancy

(in my case) to curve slightly outwards; thus the bottom of the

bowpiece will need a little extra cutting/sanding to make the bow

straight.

Next cut the sides. I pressed the blade up against the side of the

hull and then started cutting, so the bowpiece followed the same curve

as the hull. I put duct tape on the hull to protect it from

scratches, and took it off. On the port side, the saw wanted to curve

away from the hull, so I had no problems - it followed the slight

flare of the hull. On starboard, I had to section the pieces I

removed and cut in from the side to remove them, then restart the

blade; because it wanted to curve towards the hull, it's worth making

the blade flare out from the fair line a bit - this way there is some

extra to sand off when the time comes.

You recall I thought I

should have built the strongbacks with better support. Check out how

the guys at VMG

Skiffs built theirs:

Well first, wouldn't it be nice to have separate hull and deck

molds, and second, I'll bet those don't move much.

Fairing the flare

posted 2004 Jul 12

Continuing to fair the flare. It's hot, messy (you get wood dust

all over the place), exhausting work - so much so that I wrote a top

ten list and posted

it to the mailing list:

Top 10 things to ponder while sanding your swift solo:

10. How it's sure going to be nice once you get past the hull

and start on the flare (not!)

9. What your high-school football coach would say to motivate

you if only he could see you now

8. What Greg's boat will look like if only half of what he says

is true

7. What Bram would look like if half of what Greg says is true

6. "Is this good enough? No." Repeat.

5. "Boy, if I do a great job sanding I'll be able to take a swim

that much faster!"

4. How the rough spot you're sure you sanded down managed to

reappear overnight

3. Is there an Olympic event in sanding? Have I qualified yet?

2. (there is no number 2, I'm too busy sanding!)

And, the number 1 thing to ponder while sanding your swift solo:

1. top ten lists!

Must have been a long night that night. Of course, it's all

required for that fast, smooth shiny surface...

All the websites suggest using contact cement to hold the sandpaper

to the fairing board. This works ok, but it isn't a strong enough

bond. I started using Super-77 (which if anything is too strong), and

when I want to replace my paper I scrape it off with a scraper. This

makes sure the paper stays stuck.

One other note. One of the strips on the hull (below the chine,

near the bow) pulled away from the form by about 3/8", and I didn't

notice this when I put the second strip next to it. This means that I

had to plane a lot of the strip away to make it fair. When I flip the

hull over, I'll have to put a bunch of filler in the hole to

strengthen it. At this point, because of the compound twist in the

strip, I probably should have screwed it to the station.

More stripping the flare

posted 2004 Jul 4

I wound up using 21 strips on each flare - 20 full length, the 21st

strip is cut in half, the 22nd is scarfed from two pieces of scrap,

and the remaining two strips are scrap ends from the first 20. The

only note here is that the strip that is cut in half should not be cut

exactly in half (as I did) - it's better to cut one side about 12"

longer than the other. As you get towards the outer edges, the strips

don't seem to want to pull together as well, and so it's important to

pull them up with tape. Avoid the gaps - they are hard to deal

with later!

With all the strips are done, I pulled out most of the staples and

started scraping. I left some staples on the gunwales - the humidity

can change quite a bit in the garage, and I don't want the hull to

pull off the forms.

I used the scraper to get all the glue dribbles off the hull, and

to start the fairing process. I used the plane some, but I found that

because the flare is concave, the plane can't really get in to pull

any material off, and the scraper does a better job. I used the disc

sander to round the corners on the scraper blade (to reduce my chances

of scraping in a divit, although I still made a few). Just be sure to

change the blade frequently - make sure it is very sharp.

I built (another) fairing board. This one is slightly longer than

the others, and has 4mm rope tied to the ends running through a jam

cleat I can use to control the bend in the board. Thus I can sand the

concave flare. Just takes lots and lots of time...

I did the math for the bowpiece as well. I've pasted the template

to a piece of hardboard and cut it out, and aligned it on the hull to

see where things fall. When I laid down the bowpiece I currently

have, I found I could reduce the amount of wood in the bow and get

more mileage my current bowpiece by tilting it slightly - a 14°

angle. This involved a wee bit of high-school

math.

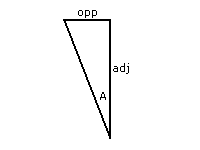

The vertical distance from the "knuckle" (the point where the bow

begins to curve up) to the gunwale is 10 5/8", and at the gunwale the

distance in where the bowpiece should come to is 2 3/4" away from

vertical. So:

opp = 2 3/4" = 2.75"

adj = 10 5/8" = 10.625"

tan A = opp/adj

= 2.75/10.625

= 0.2588

A = arctan(0.2588)

A = 14.5°

Of course, when I actually cut the bow off, I'll use the measured

distances from the stations rather than the degree measurement.

I also added another four pieces of 1 1/4" wide solid cedar to the

end of my bowpiece, adding another 5 inches of height. Now it's long

enough to fit correctly into the pattern below the knuckle of the

bow. I used the piece of solid 2x6 I had bought for this (and other

miscellaneous bits), but because the grain direction had to alternate,

I had to construct one piece wide enough with some 2" tape and epoxy.

I'm not too worried, it won't be terribly noticeable in the final

product (I think).

Page 49 of 62

« First

…

«

47

48

49

50

51

»

…

Last »