Building strongback rails

posted 2004 Mar 30

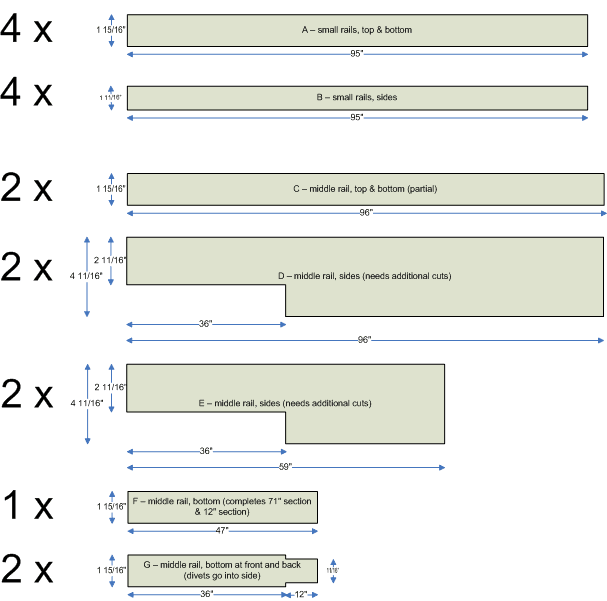

Starting with a 4'x8' sheet of 5/8" ACX plywood, I started cutting

out all the pieces for the centre and side strongback rails.

The sides are easy - cut off 1" at the end, and then cut:

- four strips 1 15/16" wide

- four strips 1 11/16" wide

While you're at it, cut another two strips 1 15/16" wide (and the full

96" long) for the centre rail.

Next up is cutting everything for the centre rail. This is a

little more complicated, because the pieces can't be flipped over to

get the "A" side of the plywood to be on the outside of the finished

piece (if you care). The best way I could think of to do it is to

flip over the plywood between cutting each of the two "L" pieces

required (pieces D & E).

Here is the picture I used to make all my first cuts (original Visio diagram).

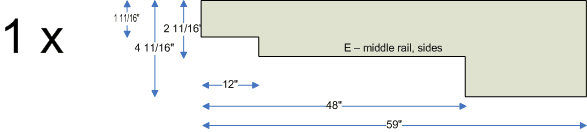

Then, one of the "short L's" and one of the "long L's" need to be

further cut down, to add a 12" divit on the end, like this:

Here is the cut list:

| | item | qty | width, in | length, in |

|---|

| A | small rails, top & bottom | 4 | 1 15/16 | 95 |

| B | small rails, sides | 4 | 1 11/16 | 95 |

| C | middle rail, top & bottom | 2 | 1 15/16 | 96 |

| D | middle rail, long L, sides (needs additional cuts) | 2 | 4 11/16, 2 11/16 for 36" | 96 |

| E | middle rail, short L, sides (needs additional cuts) | 2 | 4 11/16, 2 11/16 for 36" | 59 |

| F | middle rail, bottom (completes 71" section & 12" section) | 1 | 1 15/16 | 47 |

| G | middle rail, bottom at front and back (divits go between sides) | 2 | 1 15/16, 11/16 for 12" | 48 |

All of this I cut with my trusty circular saw, using the rip

fence to ensure the straight lines were really straight.

With all of the pieces cut, I did the work to modify the last 12"

of what will be the stern of the strongback - cut it down to 1 11/16"

for the last 12 inches. I then glued and screwed it all together.

The only thing I found when I was gluing it up was that it is

important to ensure that everything stayed straight. The plywood has

a tendency to bow, usually towards the flat A (finished) surfaces (not

the edges). On the centre rail, when I screwed the top down into the

edges, I found that the tops and/or sides "moved" slightly. The

pieces for the centre rail are arranged like this  . I

screwed the top onto the sides at the ends like this

. I

screwed the top onto the sides at the ends like this  ,

so the sides would stay vertical, and then screwed the top down over

the red area. What happened was the black gap grew tighter, causing

the rail to veer off to one side (the top in the image). I wound up

cutting out a sliver of the edge in the black gap, so the rail

wouldn't veer as much. Getting these things straight is critical.

,

so the sides would stay vertical, and then screwed the top down over

the red area. What happened was the black gap grew tighter, causing

the rail to veer off to one side (the top in the image). I wound up

cutting out a sliver of the edge in the black gap, so the rail

wouldn't veer as much. Getting these things straight is critical.

[Update 2004 Oct 5: Greg mentioned in

mail that plywood was the wrong thing to use for the rail, because it

bows due to the stress of the layers on each other. I agree - using

chipboard would have ensured the rail was straight, which would make

alignment much easier.]

I also built sawhorses. The construction manual shows divits cut

from plywood, and Kayak shows sawhorses, so I compromised. I

screwed a divited piece of plywood into the end of sawhorses. The

sawhorses stop the entire assembly from falling forward or back. On the

website, Bram says that the short one should be 24" to the notch,

and 30" on the tall one ("People over 6 feet tall may want to make

them a bit higher"). Mine are 30" and 36" to the notch, respectively.

I used plain ol sawhorse

brackets to build the actual sawhorse, and made the legs 27 1/2"

and 30". About 4 inches is added to the top of the leg when it's all

assembled.

Building side rails, epoxying stations

posted 2004 Mar 22

I glassed the bevel blocks. At first I was going to get the glass

to stick to the 1/4" wide side of the bevel block, and I was using an

elastic and some plastic to try and get this to happen. But there

were a ton of air bubbles and I couldn't get everything to stay (even

as the epoxy kicked) and so I finally gave up and just put the cloth

along the top.

I also epoxied both sides of all the stations, so they would be

less likely to expand and contract with the changes in temperature and

humidity of the garage (Bram suggests this here).

Once cured, I aligned all the centerlines and waterlines of the

stations, and drilled a number of 3/8" holes through them. This way,

when I have all the stations aligned on the strongback, I can use a

laser level and ensure that the stations are all correctly

aligned.

I then wrapped (clear) packing tape around the edges. Using

something like fibre-reinforced tape might have been easier - it's no

fun pushing down the overhang on all the edges.

Finally, I cut out all the holes for the strongback rails in the

stations. I drilled holes to allow the jigsaw blade through, then cut

everything. I went a bit overboard - station 6, where the side rails

stop, I cut out the holes for the side rails anyway. I'll have to

epoxy the pieces back in.

[Update 2004 Oct 5: Once the holes are cut in all the

strongbacks, be sure to put the strongbacks back on the patterns to

ensure the holes were correctly positioned. This ensures that you've

cut the right spot. I didn't do this and should have, it would have

made things easier during alignment.]

The spin block

posted 2004 Mar 17

I shaped the bow piece and the spin block. The parts shipment also

arrived - so I've been poking through the box and trying to ensure

that all the bits and pieces are there.

For the bow piece, I sanded off some of the curved area, mostly to

remove the rough edges, but largely left it alone. It will mostly be

cut apart when it is installed on the hull anyway. I did sand the

flat edge flat, however, to ensure a good fit.

The spin block started out as 7 sheets of glued-up strips, each 3"

x 5". Once I had taken it out of the nails and sanded it down so

there was no epoxy left on the edges, it was a block 2" wide by 2 1/2"

tall, by 4 1/2" long. I took that piece and then worked it on the

bench sander to give it a nice shape, with plenty of

extra to handle the heavy loads of the spinnaker block that will be

bolted to it. I rounded the edges, and then glassed it - the first

attempt at glassing didn't go so well, so I pulled the glass off and

will try again with a better cut piece of glass.

As an intermission from the spin block, I cut down part of the

sheet of 4'x8' into the pieces that will be used as the strongback

rails. I really need a cut sheet, so I only did the simple pieces for

the side rails and top of the main rail. Having that (clean) sheet of

4x8 also let me spread out the pieces from the parts kit, so I could

ensure everything was there.

I did the last step on the centre rail - I drilled the holes for

the vang. I used a gadget I recently picked up. It's a flat piece of

plastic which holds a metal insert exactly vertical. The metal inserts

are sized for your drill bit. You hold the plastic flat to the

surface, and you'll get a hole very close to vertical. It worked

perfectly - the holes are dead on. I used a 7/32" bit - a 10-24 bolt

will fit in 3/16", but it drops into 7/32", without touching the

sides. I filled them with epoxy, drained, and pounded the tee-nuts

into the bottom (I also found out that using a paperclip works better

to grease the threads than a Q-tip. The paperclip leaves more grease

behind.)

Spinnaker block, bow 'ball'

posted 2004 Mar 14

I completed the spin pole ring saddle. I sanded both edges to a

bevel of 23°, and the ends to 45°. I then glassed the top,

bottom and sides. When that cured, sanded off the excess and glassed

the ends.

With some of the excess epoxy/207 from the spin saddle, I put a

sealer coat on the bevel blocks. I also put a second layer on the

e-glass tape I wrapped around the bevel blocks. It flowed down to the

bottom a bit, but I think I can safely call these parts "done"

now.

I also sanded down the fairing compound on the vang pedestal and

coated the entire centre rail/vang pedestal in three coats of

epoxy/207/graphite. The second coat I didn't add enough graphite to

make it opaque, so I had to sand it down and put on another coat.

While I was waiting for everything to cure, I started work on the

spin block. For this piece, you need seven layers of wood, each layer

with grain running in opposite directions. Between each layer is

s-glass and epoxy/406 (and I added 403 as well). I glued up all the

little boards, and then using the same system as the centre rail

(nails in the tabletop) I layed up the block and weighted it down with

some paint cans.

For the bow piece, you cut 6 pieces. 5.5" is the diameter of the

top piece, and 1.5" the diameter of the bottom edge of the bottom

piece. The top edge of that bottom piece (piece F) should have a

diameter of 2.1" - the bottom edge will be worked down to 1.5". The

grain should alternate directions between each piece, to reduce the

chance of splitting.

| piece | diameter, in | radius, in | grain |

|---|

| A | 5.5 | 2.75 (2 3/4) | — |

| B | 4.8 | 2.42 (2 7/16) | | |

| C | 4.1 | 2.08 (2 1/16) | — |

| D | 3.5 | 1.75 (1 3/4) | | |

| E | 2.8 | 1.42 (1 7/16) | — |

| F | 2.2 | 1.08 (1 1/16) | | |

| - | 1.5 | n/a | n/a |

Once all the pieces are cut, I just bonded them all together with

epoxy/406/403 and s-glass between the layers. The "tower" of blocks

wants to slide apart as it gets tall, so watch out!

Centreboard trunk and spinnaker pole ring saddle

posted 2004 Mar 07

More little stuff. I'm getting to the point where I do a bunch of

construction work and batch up all the epoxy work, so I can epoxy a

number of pieces at the same time. Saves on materials, I throw out

less leftover epoxy.

Here's this weekend's work:

- I bonded a cap to the centre rail/vang pedestal with an

epoxy/405 mixture.

- Glassed the bottom of the bevel blocks. I put disposable zinc

bolts into the tee-nuts to stop epoxy dripping through, covered the

bottoms in grease, and then faired them with epoxy/405 left over from

bonding the cap to the centre rail. Put s-glass on - I should have

then pressed the glass in by putting it glass side down on the

workbench, to make the bottom flat (pity I forgot). Covered it in

epoxy/207.

- Glassed the gudgeon block already on the transom bar with the

leftover 207. Doing this after bonding them together worked out well,

it makes it a bit easier than the glass for the standalone block,

because the draping glass sticks to the transom bar.

- Cut 1/2" wide strips of solid cedar for the centreboard trunk

ends. Wrapped them in a piece of scrap hybrid, painted on epoxy,

wrapped in plastic, clamped, let cure, and then painted again with a

second coat of epoxy (when the first became tack-free).

- Bevelled the back edge of the centre rail to match up to the

vang pedestal. This turned out perfectly, I'm happy with the results.

- Cut and bevelled a number of pieces for the centreboard

trunk.

- Glassed the unglassed parts of the centre rail. Getting the

glass to settle was tricky and I wound up using an elastic to keep the

glass pressed to the edge - and I should have used plastic to keep

them apart. Epoxy bonds to rubber nicely. With a triangle file and a

round file, however, I managed to rectify my mistake.

- Faired the vang pedestal.

- Cut the spinnaker pole

ring saddle from a piece of 1" thick solid cedar. It started out

as 4" by 6", and I bevelled the bottom to match the top edge of

station 1. I then used the power sander to remove some stock for the

circular divit on the top - it should wind up to be a divit of 3 1/2"

diameter, about the diameter of a WEST System fairing container.

Bevel the sides in 23° and ends in 45°.

[Update 2004 Jul 28: it would have

been worth it to assemble the entire centreboard trunk at this point,

rather than when it had to be inserted in the hull. (instructions)

This way you work in a shop that has room rather than on a cramped

edge of your workbench.]

[Update 2004 Jul 29: also note that

Bram has a new insert

mechanism (local) which

is easiest to install when you are building the centreboard trunk.]

The centre rail

posted 2004 Mar 05

I cut the new vang pedestal in half, and then glassed both the

outer edge of the pedestal as well as the entire centre rail with

s-glass.

I also used 2" e-glass tape to glass the edges of the bevel

blocks. This required a bit of effort to ensure the glass stuck - I

painted the edges with epoxy/207, waited a while for it to get nice

and tacky. While I waited, I cut strips of e-glass tape to the right

length to wrap around the outer edges. Once tacky, I wrapped the

outside with the tape. The short edge doesn't need the tape form fit

along the vertical edge (which would cause the tape along the long

bottom side to not align), but the tape must form fit along the tall

vertical edge, which means that there are "tabs" along the bottom -

look here for what I

mean. With the remaining epoxy/207, I glassed one of the gudgeon

blocks - I'll go back and do the other one as well.

Once the epoxy had gelled up on the bevel blocks, I cut away the

overlap. The West

System instructions talk about using a sharp utility knife to cut

the edges and remove the overlap, but on such a small cut I found it a

lot easier to pull off the wet tape (once it was gelled) and cut with

scissors, and then cut the other side to match. Once you're used to

how to cut, it's easy to make the two edges match.

Once everything cured, I sanded away the excess and smoothed out

the edges. Next will be a second coat of epoxy, and glassing the

bottom surface.

I also cut the cap for the vang pedestal. I used the 3 1/2"

circle saw to get the starter shape, then mounted that on the drill to

get it down to the right size. I had problems with it turning oblong

(I botched one and had to do it again). What I wound up doing was

cutting a circle of the desired (bottom) radius, taking off a bunch of

material via the drill, and then getting the final size and shape by

holding the piece with the paper on top of it up against the disc

sander. This worked pretty well, you still have to be careful about

removing material too quickly.

Last up: I started cutting the parts for the centreboard trunk.

I aligned all the strips vertically in the trunk body, but the smaller

pieces I will align them horizontally. They seem to be providing

strength longitudinally, so horizontal strips seems to make more

sense.

Page 53 of 62

« First

…

«

51

52

53

54

55

»

…

Last »

![]() . I

screwed the top onto the sides at the ends like this

. I

screwed the top onto the sides at the ends like this ![]() ,

so the sides would stay vertical, and then screwed the top down over

the red area. What happened was the black gap grew tighter, causing

the rail to veer off to one side (the top in the image). I wound up

cutting out a sliver of the edge in the black gap, so the rail

wouldn't veer as much. Getting these things straight is critical.

,

so the sides would stay vertical, and then screwed the top down over

the red area. What happened was the black gap grew tighter, causing

the rail to veer off to one side (the top in the image). I wound up

cutting out a sliver of the edge in the black gap, so the rail

wouldn't veer as much. Getting these things straight is critical.