Building bevel blocks

posted 2004 Feb 29

Did more catching up on the little bits this weekend, and more

work on the bevel blocks.

I glassed the backing blocks on the transom. To get the right

shape, I used a blank I had cut that turned out to be too small, but

was still cut to all the right angles. I laid it down on the glass

and traced it's outline, and then cut. There were a bunch of strands

of glass floating around, but it worked out ok. Once I had applied it

and the epoxy had cured, I used a file to take off the rough spots,

which worked out pretty well.

I sealed the holes in station 6 with some leftover epoxy. This

time, instead of putting a line of epoxy over the edge while the

station was vertical, I laid the station flat and painted the inside

edges. It made a lot less mess on the sides, and while I doubt it's

as good a seal (the spots with end-grain in particular could probably

use more), it's certainly cleaner.

I cut the transom bar to roughly the correct length. I centred

the bar on the transom, then scribed where the cut should be - then

added 1 1/2 inches outwards and cut there.

I shaped a new vang pedestal. Bram says here

that the top diameter is 2" and the bottom 3", and the pedestal I

first build had a flare maybe slightly less than 3" on the bottom. It

doesn't really have the "flare" I want on the bottom edge though, so I

built another one. I bonded together 6 layers of scrap bulkhead

material (I've got plenty of that ;-) with epoxy/406, then sanded off

the excess epoxy on the edges until the cedar was showing through. I

put the cylindrical block on my drill, and used the power sander and

the drill to turn the right shape. This time, I never used the flat

part of the sander - only the curve at the end of the belt. I got a

much nicer pedestal, and it's also a lot more circular than the first

attempt (although I think this is luck, not much more). Be sure to

tighten the chuck a bunch of times, otherwise you're sure to wind up

with an oblong pedestal.

For the bevel blocks, I did the following.

- I cut all the remaining blocks out of the bevel, each 4" by 2

1/2". I botched one because I cut to aggressively at the end of the

cut, and ripped out the wood. That one was put to use as my test-bed

for testing hole sizes.

- I bevelled in the sides on all the blocks, 7° on the sides

and tall edge, and 12° on the short edge. 12° seemed to look

a bit better than 7°, 7 just wasn't enough. I also shortened the

blocks down from 4" a bit so that a clam cleat fit with maybe 1mm

extra on the top and bottom.

- I sanded the vertical corners to round them down a bit. A

block is best for this, the ROS is too big and unwieldy for it.

- I marked the spot where the holes should be drilled, by

putting the clam cleat on each block and marking the centre of the

mounting holes. Two cleats per block. Each hole should be 3/8" in

from the edge, this is the radius of the tee-nuts.

- Pound a starting mark with a nail, then drill all the holes

with a 5/16" bit. This is slightly wider than necessary, but it makes

the bolt threads go through cleanly. When they're drilled, clean up

the glass side hole with a triangle or circle file. The only trick

here is to make sure that for the bottom holes, you drill at vertical,

but with a very slight angle back, so the hole is maybe 5° off

vertical towards the narrow edge. I did this by drilling as soon as

the "level" light on the drill went on. This makes sure there is

enough room for tee-nut on the bottom edge.

- Grease the threads on all the stainless steel tee-nuts, and

then drill out a slightly larger (3/8") hole for the shaft of the

tee-nut.

- Cover the bottom holes with tape, putting the tape on the side

if the drill ripped out any wood on the bottom edge.

- Mix up some straight epoxy, then fill up the holes with a

syringe. Keep the holes full, as the wood absorbs the epoxy. Watch

the remaining epoxy in the mixing container - when it starts to get

thick or appears to kick, pull the tape off the bottom and let all the

epoxy drain out. Wipe the bottoms, and make sure there is no epoxy

"skin" covering up a hole.

- Pound the tee-nuts into the bottom, and then run a Q-tip

through them from bottom to top to clean out all the wood chips that

might be in the path of a bolt in the hole.

Epoxy Rash

posted 2004 Feb 28

I managed to get a small dollop of uncured epoxy on my forearm by

my wrist, and because I was right in the thick of epoxying stuff I

didn't clean it off immediately. Big Mistake. I can safely say that

when the MSDS sheets say

"May cause moderate irritation to the skin such as redness and

itching" they weren't kidding. I've had a small poison-ivy like rash

at the spot for a week now, and it itches. If I knew

then what I know now, I would have stopped immediately and cleaned the

epoxy off.

• • •

When I cut the cloth for the transom, I cut the 50" wide s-glass

into three strips (like the Netherlands flag) - one

each for either side of the transom, and a strip left over which I

just hung onto, figuring it would be useful at some point.

And how - all these little pieces need more little pieces of

glass to go over them, and that strip has proved very useful.

On Corrosion

posted 2004 Feb 26

I went down to the local Home Depot to pick up tee-nuts to embed in

the bottom of the centre rail/vang pedestal, as well as the bevel

blocks I just built, and while talking to the guy about thread counts

(he suggested 10/24, which Bram later confirmed),

he suggested using stainless steel for the bolts. Reduces rust. I

knew that different metals would cause problems with corrosion, and

all they had were zinc tee-nuts, so I started to wonder how to fix

this problem. Could I drill a slightly larger hole and embed a SS nut

& washer?

So, I joined a Sailnet

mailing list for Puget Sound sailers, and asked there. I got a few

good responses:

Ken Fischer (ksfischer@mac.com) suggested

Were it me, I might well go with your idea of using SS nuts and washers.

Try cutting a hole in a piece of wood of similar thickness to the

nut and washer. The diameter of the hole should be a bit larger than

the washer.

Put a piece of tape across the back side of the wood. Superglue

the nut and washer together and then stick them down to the tape,

inside the hole. Use a dab of tape to cover the top of the nut, as

well.

Mix some epoxy and use a brush to just wet the wood inside the

hole, and the surfaces of the nut/washer, which you would have cleaned

with acetone. Then add cotton flox to the epoxy until it is a thick,

but wet paste. Use that to fill in the area, essentially making an

epoxy casting.

When cured, peel the tape and you should have a pretty good nut that

can be glued to the back side of just about anything, with no worries

of the nut falling or breaking off.

Duncan Forbes (duncan.forbes@ints.com) suggested

Now onto your problem, I don't think zinc plated nuts would be a terribly

good choice. I would think stainless would be the way to go. Where have you

looked for T-Nuts? I popped out onto the internet and did a quick search and

found a couple of on-line sources for stainless T-nuts. However not knowing

the size you need I couldn't find an exact match. I used a google search for

the keywords "stainless steel t-nut".

Here is one promising link though: stainless

tee-nuts.

Another writer suggested that anything I could describe I could

find at mcmaster.com, which

after a bit of searching does indeed seem to be the case...

I also took a book out of the library: "Metal corrosion in boats:

the prevention of metal corrosion in hulls, engines, rigging, and

fitting", by Nigel Warren (Dobbs Ferry, NY: Sheridan House, 1998).

This was way overkill for my purposes, but it did have some nice

pictures of how nasty corrosion is, and you don't need two different

kinds of metals...

Here is more information I collected.

Catching up

posted 2004 Feb 25

This week has mostly been devoted to completing all the little

things that I haven't done in previous steps. i.e.:

- I cut the vang pedestal in half with my trusty razor saw (have

I mentioned how much I like this saw?), and bevelled the straight side

to 10° inwards to match up with the centre rail.

- I cut the breather holes (but not the drain holes) in station

6. I used the old station 6 to place the locations of the small 2

1/4" holes, and then measured out the positions for the 3 1/2" holes -

being very careful to ensure they were at least 4" apart. The drain

holes I'll drill later when I can ensure that they match up well with

the centreboard trunk.

- I laid down the carbon tape on side two of station 6 (side one

I did while I was applying hybrid to the board). Scraped it up with

40-grit on the sander, then used a brush to apply the epoxy to two

pieces of overlapping 1 1/2" carbon tape. Applied a second coat of

epoxy when the first was tack-free. [Update

2004 Mar 15: It may have been a good idea to put peel-ply and

plastic down on top of this (and then perhaps a layer of thin foam, so

the epoxy doesn't just migrate to beside the tape), then a board, and

clamp it down. This would have reduced the total epoxy used, and

would have made things a lot smoother and flatter. Next time, I

guess.] [Update 2004 Mar 22: I think

also it might be a good idea to vacuum bag both the bulkheads, just to

reduce the total amount of epoxy in the hybrid. Greg talks about this

here.]

- Put a 25° bevel on the bottom ends of the T-soldiers,

using the disc sander and the angle guide, then used extra epoxy from

the carbon tape to seal the exposed edge of the bevel.

- Cut a piece of scrap bulkhead hybrid, 6" wide, to use as the

backing block for the gudgeon which goes on the transom. I traced

around my hardboard pattern to get the right shape.

- Cut and bonded the backing block for the transom bar to the

backside of the transom. Take a piece of solid cedar, 12" long by 2"

wide by 1" thick, bevel the back edge to 45° picture. Cut in half, and

bevel the inner edge to match the transom 'step' edge (about 20°).

Once that's done, bond the piece to the back of the transom. I inset

mine about 1/8" so there's a bit of extra to sand down when the deck

is installed, and it makes it a bit less messy because the epoxy can

collect in the 1/8" lip. I used epoxy/206/406 and a bit of s-glass

for the bond - in retrospect the 2" e-glass tape would have worked

better because the edge is finished on the tape, and strands of glass

wouldn't be pulling out and it's exactly the right width. The block

wants to slide all over when you apply pressure, and the glass wants

to slide out, so be careful.

Building the centre rail

posted 2004 Feb 22

I've been doing the construction of these parts a bit out of order

- since I built the strips for the centre rail, I figured I would lay

those up and do the work for them, while I was completing other

parts. At this point the book starts building the centreboard trunk

and mast step.

So, I layed up the centre rail - epoxy/206/406 together and 2"

e-glass tape every other layer, three strips wide and 6 strips

high. (I had previously built the 3 wide strips.) I used nails

hammered into my trusty workbench to ensure that the pieces didn't

slip out sideways - this worked pretty well, cheap, easy, and didn't

involve clamping, which would have been hard. Even with my experience

with the transom bar, I still had a couple voids, and I had even taken

a couple strips off and re-applied extra filler to ensure that

everything was nice and full. I guess excess is the order of the day.

I weighed down the layup with paint tins and glue - just make sure

they are applying even pressure side-to-side.

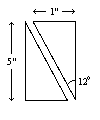

While the rail was curing, I worked on the bevel blocks. For

these, you take a 5/4" by 6" piece of solid cedar, and cut it 16" long

by 5" wide. Then split it on a bevel of 12°. This completely

confused me (although in retrospect I'm not sure why...) - the split

should look like this:

12° is (basically) the exact angle that cuts the piece in half

along a diagonal between opposite corners, when looking at the piece

end-on.

Well, I had a piece of 2x6 solid cedar, and I choose to interpret

5/4 as 1" (Bram indicates this is about right here

although it depends a lot on who you ask - 5/4 is a rough lumber

dimension, and when it gets surfaced it changes). I tried taking a

bit of the height off with my jack plane, but it would have taken

forever. And then how to cut something on a 12° angle?

The woodworking alias came to the rescue - someone assisted in

planing it down, and ran it through his table saw for me. I think

this is the only spot where I've really needed one.

That accomplished, I took one of the bevelled pieces and, along the

bevelled side, stacked the following:

- a thin layer of epoxy/206/403 on, to seal the wood

- a layer of e-glass

- another layer of epoxy/206/403. Note that I'm using 403 here

instead of 406 - it seems like a better choice for this usage

(laminating instead of bonding).

- a layer of strips, cut to 5" long, with the 206/403 mixture

between strips. 5" was just barely enough to cover the length of the

bevelled edge.

- another sealer coat of epoxy/403, this time with 207 hardener

(since we're on an outside surface now).

Apply pressure and let cure overnight. All in all, pretty quick.

Once that had cured, I did the following:

- sand down the surface (pretty quick with a fresh 40-grit pad an

a random orbital sander)

- seal the bare wood surface with epoxy/207/403

- apply another layer of s-glass, and let everything soak in

- finish off with epoxy/207.

With the centre rail cured, I cleaned it up and took off all the

extra epoxy on the sides and top/bottom. I then used the disc sander

with the table adjusted to 10° to bevel both sides to the right

angle. My kingdom for a table saw - this would have taken two

minutes, and been more accurate, with one. But the sander worked out

pretty well, as long as you're careful. I also bevelled the last six

inches of the end of the centre rail - so it tapers down from the top

to 1/8" from the bottom.

Oh, and I also bonded the rudder gudgeon to the transom bar,

cleaned up a little extra s-glass which was sticking out (using duct

tape to protect the bar), and added a fillet of epoxy/207/406 to the

edge.

[Update 2007 Feb 3: There was a

question on the list

about the dimentions of the centre rail; Bram's rail is 1 3/4”

at the bottom and 1 1/4” at the top. Mine is a bit wider

— 2 1/4” at the bottom, 1 1/2” at the top.]

Building the transom bar

posted 2004 Feb 18

I wrapped the transom bar in graphite tape, and then 2" e-glass

tape. Before doing this, however, I coated the edges in epoxy with

406, in an attempt to fill in some of the cracks there. I'm not sure

this was completely successful, but it did help in one way. When I

came back to put the carbon tape on, the epoxy was still fairly tacky

- which meant that I could wrap the tape around, and then press it in

to the tacky epoxy and have it stick, so it wouldn't fly off again.

This helped a bunch.

With the carbon tape on, I first coated it in epoxy/207, and then

wrapped the 2" fibreglass tape around (with the edges running in the

opposite direction to the carbon tape). I then coated the entire

thing in a mixture of epoxy/207/406/graphite powder. Later, I came

back, sanded down the bar to take off some of the high edges where the

tape overlapped, and put down another layer of epoxy/207/406/graphite.

I probably should have used 403 or 405 for this application, since

from Gudgeon's handy

dandy chart it would have been less dense and more suitable to the

goal of mostly fairing with some strength.

Bram posted weights of some of the parts. Here's his list, and my

weights as well:

| Part | Target Weight (g) | My Weight (g) |

|---|

| Station 6 after holes | 1005 | 1233 (old station 6, tape on one side)

1430 (new station 6, tape both sides, no bottom drainage holes) |

| Station 8, both halves | 934 | 1195 |

| Toe rails | 1012 ea | ? |

| bevel block for sheaves | 58 ea | ? |

| Cleat bevel for clam with T-nuts | 72 ea | ? |

| Partial bulkheads, all 3 sets | 902 | 1130 |

| All 8 soldiers | 338 | 1160 (!) |

| Transom bar | 900 | 1160 (rough-cut) |

| centre rail w/ T-nuts and vang pedestal | 525 | ? |

I'm not really sure why I'm over so much: it seems like this is a

lot, especially to chalk up to just extra epoxy on the bulkheads or

something. Maybe I've got extra-heavy cedar? Maybe someone's scale

is wrong?

Turning the vang pedestal

posted 2004 Feb 12

I set to work on building the vang pedestal. To do this, you take

the bonded 3 1/4" discs, clean out the centre hole with a 1/4" drill

to get rid of the excess epoxy, and then put a bolt through the stack

of discs. I used a couple fender washers to protect the surface of

the discs; I used a bolt which was too long and added extra washers to

make sure I had as much thread left over as possible when the

tightening nut was on. Tighten up the nut tight, and then take the

thread-end of this and put it in your drill. Really secure this in

tightly - if you don't, it's going to come spinning out of your drill

(experience talking here).

Turn on the belt sander, and fire up the drill, and start taking

the side off. This works pretty well, but the discs have a tendency

to bounce off the sanding belt, so you wind up with a

not-quite-circular assembly. Press hard against the belt to reduce

this. The bolt threads will start to unscrew out of the drill, if you

see threads stop and put the bolt further into the drill (and tighten

harder).

Initially you just want to get the entire edge smooth. This

requires keeping the drill horizontal to the belt surface. Once the

entire edge is smooth, you can start shaping it into the right curve.

I found I had to press the top half of the cylinder into the end of

the belt at 45° to get the right shape - flared out at the bottom,

and a slight flair at the top.

• • •

Started building the transom bar yesterday. I took the 2x6

generously cut by a friend of mine on his bandsaw, and put duct tape

over the curved edge. [Update 2004 Mar

10: when cutting pieces for the centreboard trunk, I broke a blade

and put a new one in which was a lot longer and thicker than the thin,

curve-cutting ones I was using. I realized that I could probably have

cut this 2x6 with the jigsaw with this longer blade.] I cut 14

strips, 6x55" long, 4x56" long, and 4x57" long. I put epoxy/406

(cream) in the cove of a 55" strip, laid it down on the duct tape, and

clamped it down, and then put another strip alongside it, squeezing

some of the epoxy out. Cover that entire surface in epoxy/406, add 2"

tape, more epoxy/406, and then put another two strips down. Keep on

going until you have a stack 7 high.

The hardest part of this entire thing is keeping things clamped

down while you add more strips on. The strips want to escape

(obviously) - I suppose I could steam them or heat them, and this

would reduce that springiness (although it would make the epoxy more

fluid and harder to control, it would set up much quicker). Keeping

C-clamps on the end is hard, because they want to slide off the ends -

I think the trick here would be to cut a notch in the bottom edge of

the 2x6 so that there is a spot for the clamp to hang on to that's

relatively parallel to the angle of the strips at the end.

I think in retrospect I would build the bar this way:

- Cut three 4" by 12" strips of plastic.

- Cut the strips: 4x 55", 4x 56", 4x 57", 2x 58". Cut the 2"

tape as well, 1x 55", 2x 56", 2x 57", 1x 58".

- On your workbench, lay up the strips two wide, seven high,

with 2" tape between each layer. Use epoxy/205/406 (heavy cream).

You may need to use 206 to slow down the curing a bit.

- Once everything is laid up, wrap the plastic around the

layup at the 1/4, 1/2, and 3/4 points. Put spring clamps vertically

at these points to stop the strips from sliding sideways.

- Take the layup, and put one end against the jig. Clamp

and/or tape that end to the jig. Then bend the entire layup over the

jig, and clamp the middle. Bend the other end down, and clamp/tape

the end.

It might also have been a good idea to have the template laying

on it's side on the workbench, rather than having the bottom edge on

the bench. This way it would be easier to clamp and the strips

wouldn't be able to slide out as easily.

I'm not sure how it would bend, but it seems like it would be a

lot easier than fighting with individual strips that are springing

loose when you release a clamp to try and get a new strip down. The

layup is slippery, so it's hard for the clamps to get a grip, it's

hard to get the epoxy under the tape where the clamps are holding,

tightening the C-clamps causes the strips to get twisted and slip

sideways, and when you add a new strip all the previous strips pull the

tape out and you have to fight to get it back in place.

I also discovered (the hard way) you need to clamp the middle,

otherwise the layup won't get a good solid bond, and there will be air

holes in the middle - you can't see this while you're working either

because there's just a big mess of epoxy and tape.

[Update 2005 Aug 15: there was a conversation

about how to build the jig for the transom bar, including a picture

of Rob's jig. He cut the 2x10 into two pieces (in a long arc) and

then clamped them together with the strips in the middle. This is an

even better idea - no voids, no wrangling with bits of plastic, no

problems with individual air pockets.]

Cutting the transom

posted 2004 Feb 08

I cut the transom. This was just like cutting the bulkheads or

the stations - line everything up, making sure the strips are exactly

parallel to the waterline, put the pattern paper side down, and trace

around it with a marker for the rough-cut line. Then cut it out with

the jigsaw, and then route around the pattern. I've found that doing

this rough-cut step makes taking off the excess with the router much

easier, especially if there isn't a lot of excess to remove. I

managed to avoid destroying the template for the station this time too

(!).

Next up was completing the centre control block bevels. The

bevel for these starts from 1/4" up from the bottom, and is 23°

off horizontal (i.e. 67° off vertical). The feed table for the

belt/disc only go to 45° - some other method is required.

Here's what I did. First, I put the table so it was set up for

the belt, and adjusted it to 23°. Then, I clamped a straight-edge

along it that I knew wouldn't flex much, and adjusted the belt so that

it's base was parallel to the straight-edge (picture). Thus I know the

belt is exactly 23° off horizontal.

The table is too far from the belt to be able to feed material

into it, so I needed to create a platform to feed things in. I dug up

a scrap piece of 2x6 (the end of the transom jig 2x6) and first used

the table to sand down the end, and then took my pull saw and cut off

an additional piece parallel to the sanded edge. I drilled two holes

on the table, and two on the wood, and bolted the wood to table (see

here).

Feed in the block, and when there's about 1mm remaining at the

closest point, stop and move to another side. The belt is good for

starting, but not finishing. The belt curves up on the sides, and so

it's better to finish with the disc sander, as it is perfectly flat.

And since the angle formed by the two edges is 45°, you can use

the normal feed table.

For the disc, you have to be careful that the right side of the

disc (which is moving upwards) won't rip the piece from your hands and

give a weird angle. I found that if I gradually moved the block

closer a small amount (1mm), then press the bottom edge onto the table

(thus pushing the top edge into the disc), I could reduce the

likelihood that the block would "jump" and pull off some weird angle.

I also cut out six 3 1/4" pieces from the scrap transom and

bulkhead material for the vang pedestal. I roughed up the sides with

the random orbital sander, then used epoxy/205/406 to bond them

together (no need for extra glass). I put a 1/4" bolt through the

centre hole while I was getting everything together, then removed it once I had the

clamps on.

Continuing the transom

posted 2004 Feb 05

Did a few things this week.

First, I scribed out the 72" arc required for the transom bar jig

on a piece of 2x6. The board is a bit too wide for me to cut with my

trusty jigsaw, a handsaw won't cut it, cutting a curve like that with

a circular saw won't work. And so a friend is going to cut this out

on a bandsaw, the ideal tool for the task.

I took the pieces I bonded together for the rudder gudgeons and

used my (newly assembled) belt/disc sander to take off all the extra

epoxy and glass. This flew by - that belt sander can really remove

material. I then set the table up for the 45° angle on the ends,

sanded that off, and the 12° angle on the sides - absolutely no

problem. Making this part was pretty fun.

I bonded the 4-strip wide pieces of the centre control block

bevels together. This is the same as the rudder gudgeons - epoxy/406,

leftover s-glass between the layers, and clamp it together. Be sure

to protect the top and bottom from the pressure of the clamps - I used

a couple small sheets of plywood this time. Also, have clamps

clamping all three axis (I didn't do one, the one with the length of

the strips). The strips will slide out in the direction you don't

clamp otherwise. My strips were cut at fairly tight tolerances, and I

got lucky they didn't move so much that I had to rebuild the piece.

I had some extra epoxy/406, so I decided to cut and glue together

the 32" strips needed for the centre rail. This time I used epoxy

rather than carpenter's glue. Compared to glue, epoxy is hard - when

I came back later and knocked off the excess resin, the epoxy takes

quite a beating...

Next up was the backing block for the transom bar. This is built

from a scrap piece of dimensional cedar. Since I bought all mine, I

made a trip out to Dunn Lumber

and picked up a 16 foot long piece of 2x6, with nice tight end grain -

expensive, but ideal for what I need (I'm not sure how people build

cedar decks, it has to cost a fortune). I used my newly acquired

circular saw to cut a 45° cut with the grain in from the end, and

then a 90° cut parallel one inch further in. (You can see the

lines here.) I then cut

off the piece, and put it on the belt sander to take it from 1 1/2"

thick down to 1" thick. A planer would have been handy here, alas.

I scraped, planed and sanded the second side of the transom

material. There is a slight bow away from the already glassed side of

the transom - I'm not sure exactly why. Perhaps the temperature

changed slightly, or the humidity, or perhaps even the glue

between the strips tightened up and pulled together a bit. It's not

terribly noticeable, so I'm not too worried about it. If I had hit the

second side with the sealer coat sooner, it probably wouldn't have

happened. (Note to self: be careful leaving the hull unstapled...)

Like the outside edge, I laid down a sealer coat of epoxy/406,

with 205 hardener. Once that had reached almost tack free about 8

hours later, I sanded it down a bit to provide rough surface, and laid

out the satin s-glass. I worked this in quite a bit this time - the

sealer coat was still a bit tacky, and so the glass stuck to it.

Getting all the air bubbles out is worth the time, however, they are

easy to see when you're done (as I found out from the first side). It

will probably be worth it to go over the entire exterior hull and

putty all the staple holes, just to eliminate the bubbles - they are

really easy to get, otherwise. Saturating the glass took about 9

squirts of epoxy, and I probably pulled 3 off to get it to "wet, not

shiny".

Because it's cold, I've been heating the epoxy resin in front of

the space heater before mixing it with the hardener. This makes a

difference - the epoxy cures faster, and it's easier to work in

(because it's less viscous). I almost didn't catch the "tack free"

stage after applying the glass because it cured so much faster.

[Update 2005 Jul 28: it may have been

better to use hybrid on the back side of the transom, for increased

strength. Greg suggests that here.]

Building the little bits (2)

posted 2004 Feb 01

Next up is preparing the outside surface of the transom. I

scraped off as much glue as I could (without seriously damaging the

strips), then planed it flat with my jack plane. Next up was using my

new Makita random orbital sander - this sucker *rocks* and works much

much better than the DeWalt sander did.

With the transom piece sanded flat, I mixed a sealer coat of

epoxy up. Because it's an outside face, this needed 207 "Special

Coating" hardener. To improve the stiffness, I also added a little

406. 207 gives the epoxy a yellow tint, which I don't like as much as

the plain colour, but given that it also makes the surface much less

prone to UV damage, I'll live with it. ;-)

While that was curing, I used a paintbrush to coat the second

side of the small pieces with epoxy/205. I then moved on to putting

2" e-glass tape along the bottom edges of the T-soldiers. This is

simple - straight epoxy, just saturate the fabric and bond it right

on. This would have been a good spot to use peel-ply - this way a

bunch of the excess resin could be forced out, while ensuring that the

slight overhang of the tape over the edges of the strips could be

wrapped around the strips, keeping the tape tight to the strips.

Peel ply is a fabric-type release

material used in vacuum bagging. It is usually teflon coated

fibreglass for high temperature molding, or nylon for room temp

work. Epoxy will wick through it (similar to wetting out glass) but

the epoxy won't stick to it. The wicking action will remove excess

resin from the layup. When the epoxy has cured, you peel the material

away from your laminate, taking the excess resin with it. You are left

with a rough-textured surface which helps when you want to bond

additional layers or parts to this first layup. (from here.)

Once the epoxy on the transom board was dry, I hit it with a

sanding block to take off some of the high spots. The particular

spots to worry about are the "ridges" that are created by drawing a

squeegee along the surface - the resulting line of epoxy that runs the

length of the draw. With those knocked, off, hit it with the vacuum

being very careful to get all the little bits of dirt, sawdust and

epoxy dust off.

Then, lay down the s-glass. The s-glass is a 2x2 satin weave,

and it's very sheer - the slightest imperfections will show through

the material. Small bits of dirt or dust will become bumps on the

surface. Use the brush to flatten it out, and be sure to take some

time to do this - it is much harder to work bubbles out of this stuff

than the hybrid.

Apply resin/207 mix. I was surprised at how little was required

for this surface - a lot less than the hybrid. I was prepared for 10

squirts, but only needed about 8. It's also important to work out the

bubbles. Using the roller, or fingers, it's often easiest to work the

bubbles to the edge of the board than to get them to "blow through"

the glass, and it's a *lot* harder to get rid of them all than it was

for the hybrid. Worth the effort though - those bubbles are weak,

unbonded spots.

While that was curing, I bonded all the boards together for the

rudder gudgeon. I used epoxy/205/406 as the glue with layers of scrap

s-glass between all the boards - board, glue, glass, glue, board

(repeat). Once this was all set up, I wrapped it in plastic and

clamped it all together to get a good solid bond between everything.

Don't forget to put a buffer block between the cedar and the clamp -

you don't want to (like I did) make a nice round dent in your cedar.

(Fortunately, I can put the dent on the side facing the transom...)

Once the transom had reached tack-free, I came back and used a 2"

paintbrush to apply a second coat of epoxy/207. I managed to loose a

bunch of bristles while doing this, and it's a hassle to fish them

out, but it would be ugly if they showed through.

Page 54 of 62

« First

…

«

52

53

54

55

56

»

…

Last »