Stripping the deck

posted 2004 Dec 31

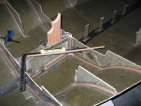

Now that the hull is complete and hung, it's time to work on the

deck. I flipped the strongback over, and started by making sure

everything was aligned. The list

had said that stations 11 and 12 might need to be bumped up slightly

to ensure everything was fair. In my case, I had to do a couple other

adjustments - station 11 up around 1/8", station 7 down 1/8", and

shims (one or two layers of Cheerios box) on a number of other

stations. The biggest shim was on station 3, probably to match

the shim I put on station

5 on the hull. I determined all this by laying a strip down the

middle, and then checking to see if the strip touched or needed to be

pushed to touch the station.

With things aligned yet again, I used my new bandsaw with my custom fence to cut my

accent strips. These strips are regular 3/4" yellow cedar, but I

decided to cut them slightly narrower for a bit of flair. My dad

acted as an infeed, pushing the strips against the fence, and I pulled

them through, and generally we got quite straight cuts (which you

might not expect from a bandsaw). It wasn't perfect, but it was

pretty good.

I then cut the bevel on the first two strips, numbered everything so I

would know the right order to install them, and stapled down the

centre strip. This one has to be perfectly straight since

otherwise all the other strips are going to curve around with it. For

all these centre strips, I taped them to each other to

be sure I had good contact - I want to avoid glue lines if possible on

the deck.

With all the sighting to get strips straight, I found that some

stations didn't seem to be perfectly fair. I wound up going back and

pulling the staples for a few stations, and installing shims

underneath. I did this at stations 8 (1 layer), 9 (2 layers) and 11

(1 layer). Two layers adds about 1/8". These are small adjustments,

but they seem to have improved the lay of the strips - anything more

seems pretty minor. It's frustrating to have to make these adjustments

now, after spending all that time truing the hull side of the

strongback...

I had been worried about how many strips go in the centre, but it

turns out that's not really a problem. Once the strips start to curve

up the sides (and need

screws to keep them in place) you know it's time to install the side strips. I stapled it

at station 7 first, then worked my way to the stern (with it hard up

against the wing step). I then bent it in place to the top edge of

station 2, made sure it looked fair all the way along, and stapled it

down from station 2 back to station 6.

Next up was the jumper

strip which jumps from the outer strips to the centre strips.

This one doesn't fit quite perfectly, it doesn't leave a nice flat,

fair surface after it's in place - but it's going to be covered with

fairing filler anyway. After that piece, it's pretty much just

installing strips as on the hull.

Hanging the hull

posted 2004 Dec 12

Well, I've finally managed to get the car back in the garage, after

ten long weeks of being

parked outside. Max was staying over for the week, so with an

assistant to help out, I was highly motivated to ensure the hull was

hung and the jig was flipped over so I could start on the deck.

My design was largely based on the Harken Hoister installation instructions, but beefed

up to support more weight. The components could probably handle 300

lbs; the trusses should be able to support that as well.

First was installing the trusses. I used 3" long 1/4" lag screws

to screw the 2x4s on to the truss - for each pulley, four

screws. (Remember that the trusses in this house are not 2x4s.) The pulleys are

1/4" eye bolts with the tail of the eye cut off (so the pulley would

fit on), then bolted to the other side with a fender washer and two

cross-tightened nuts. I centered the pulleys between the ceiling

joists to evenly distribute the weight.

With the trusses and pulleys in place, I installed the rope and webbing. The webbing has

hooks on the ends - I tried to saw them off with my hacksaw, but

couldn't make a dent in them. I guess there really is a difference

between different steel manufacturing methods. The webbing is tied on

with a figure eight knot - tie a figure 8 in the rope, then take the

tail and put it through the webbing loop, then make the tail follow

the trail of the figure 8 again.

Next up was the wall

2x4 screwed into a top support. It shouldn't be screwed into a

stud - rather it should go into a horizontal support that runs all

along the wall. That eye bolt is pretty beefy - but can only support

400lbs of weight. I then installed the winch at the bottom, and now

things are ready to hang. I threaded the triple blocks and the hoist is

ready.

The hardest part of all this was figuring out how to replace the

centre pulley system on the original hoister. My original idea was to

use two large Home Depot pulleys attached by a quicklink, and have all

four lines go through the pulleys. This didn't work - the pulleys

weighed too much and didn't run. So I picked up two blocks attached by

a ring, and only put the line on the front through the pulleys (there

isn't enough room for all four). The ring won't fit through the metal

pipe-holder. It would have been better if it was hanging from it -

better clearance for the line. Maybe an eye-bolt would have worked

here? (With an eye bolt it could be twisted for the right

alignment...)

And, with all that complete, we have a hoisted boat! Now I just

have to find a place for the cradle. It weighs 56.5 lbs (pretty

heavy, I have to admit). I considered hanging it too (it will fit

over the garage door, I'm pretty sure), but at the moment I'm tired of

figuring out how to hang stuff from the ceiling. So I just put it behind the workbench.

All told, this hoist cost me about $270, compared to the Harken

Hoister cost of $200. My solution will hoist an additional 100 lbs at

least. Of that $270, $32 was on the winch, and $115 on the three

Ronstan blocks I needed.

| qty | item | supplier | safe working load, lbs | breaking load, lbs |

| 2 |

Seadog stainless flush-pin D-shackle | Fisheries Supply | | 3300 |

| 100' |

1/4" poly rope | Home Depot | 95 | |

| 2 |

10' cam buckle tie down | Home Depot | 400 | 1200 |

| 1 |

Ronstan RF30302 30mm triple block | Fisheries Supply | 1100 | 2420 |

| 1 |

Ronstan RF30312 30mm triple block & becket | Fisheries Supply | 1100 | 2420 |

| 1 |

Ronstan RF30286 30mm single linked blocks | Fisheries Supply | 660 | 1650 |

| 50' |

3/16" XLS Yacht Braid (white) | Fisheries Supply | | 2200 |

| 1 |

Fulton T600 trailer winch | West Marine | 600 | |

| 4 |

1 1/2" awning pulley | Home Depot | 110 | |

| 4 |

1/4" eye bolt (to hang pulleys) | Home Depot | 90 | |

|

1/4" fender washers, 1/4" nuts | Home Depot | | |

| 1 |

1/2" eye bolt (attaches to wall) | Home Depot | 400 | |

|

1/2" fender washer | Home Depot | | |

| 18+ |

3" x 1/4" lag screws, 1/4" washers | Home Depot | | |

| 1 |

5" nylon cleat | West Marine | | |

I stress

tested the 1 1/2" awning pulleys with 1/4" eye bolt assembly (and

the 1/4" poly rope) by hanging 180 lbs on them (my weight). Nothing

broke (or even creaked), so everything seemed to be within breaking

limits.

Making the chainplate blocks

posted 2004 Dec 3

The deck plan says the centre hole for the chainplate blocks should

be 91" aft (measured from station 0 - you can use bulkhead

positions to find this location), and 29" out from centreline,

port & starboard. I put a post in the trunk and then used a

carpenter's square with a wood extension to find 29" out. Initially I

used the same 2x6 to find centre as I did to check for vertical - but

I found that the 2x6 has a slight cup, and so the square wouldn't sit

quite square on the post. This lead to a noticable (1") difference in

the position of the holes on the hull, relative to the bulkheads and

edge. I switched to a piece of solid cedar I had lying

around (which is flat) and the measurements got much more agreeable.

I also switched from a piece of strip as the extension to a piece of

metal strip - the metal is thinner and straighter. Be sure when you

do this to measure the 29" out from the actual centre - the far edge

of the post is a bit past the centre, and so an adjustment is

required.

I also wanted to ensure that the drill guides I have would drill

vertically, since I'm drilling a 1/4" hole in a 1" wide piece of

cedar. They're dead on - the drill guide has been very useful.

So, with a rough idea of where the cedar would go, I transferred the angles to

the 1" thick cedar block, and cut the piece. I then planed the bottom edge down

to the angle of the hull, and checked for fit. The

chainplates are supposed to be parallel to the edge of the hull, and

installed so they are at 90° to the deck (or slightly turned

inwards). I measured everything so they would be slighty turned

inwards, but there's a lot of play in the blocks and a slight turn

causes a lot of difference in the hole position. I cut away the top

edge so it matched up with the top edges of the gunwale, and also put

a slight inwards angle on it with the plane.

I set about cutting the second one as well. I drilled holes in the first

plate (centre hole and the two outer holes), but decided not to on the

second one. The chainplate position is a class measured position, and

I want to try and gain some additional accuracy when I fit the deck -

I'm a little concerned about the cumulative error of all the

measurements from measurements I'm making. Being out 1/4" on the

position of these holes wouldn't be good.

Page 44 of 62

« First

…

«

42

43

44

45

46

»

…

Last »